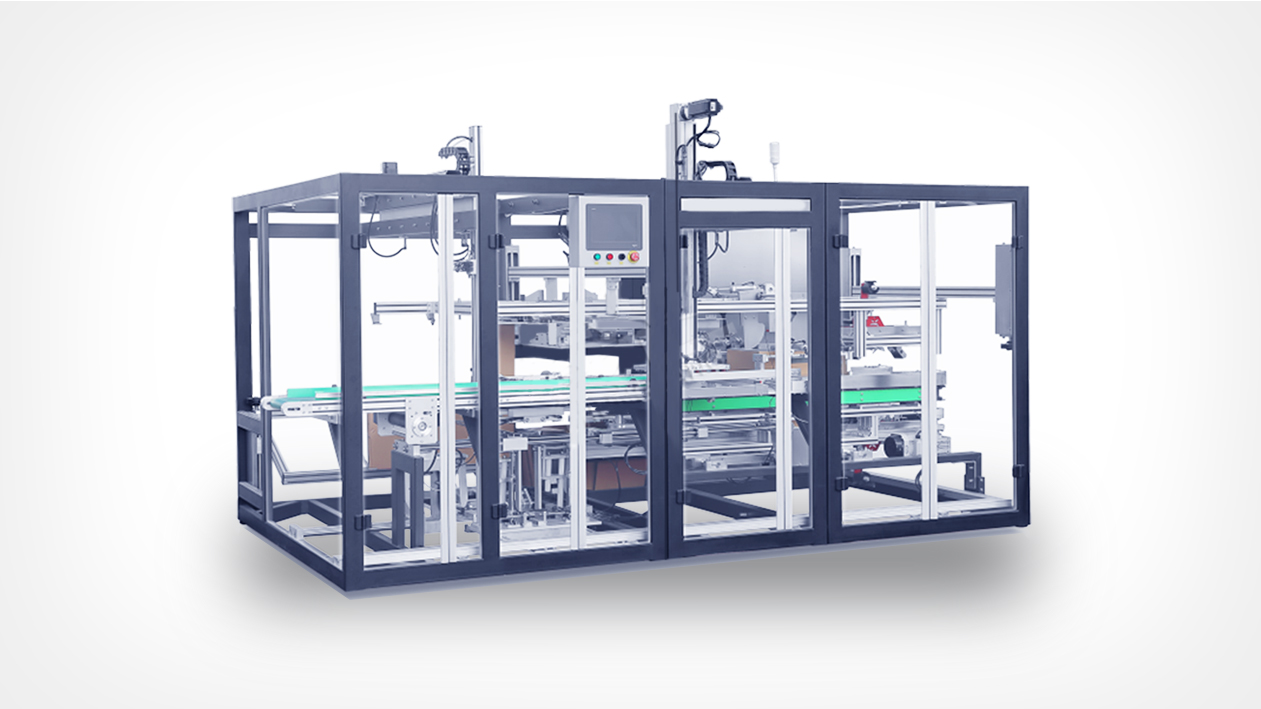

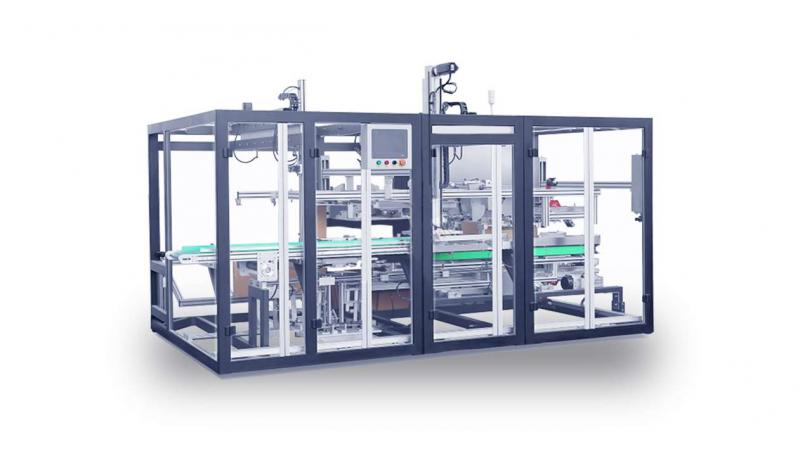

Brief Introduction of Equipment

The KZF550 unpacking, packing and sealing integrated machine has a reasonable structure and is easy to operate. It can automatically realize the functions of unpacking, packing and sealing.

Product Features

1. The frame has a reasonable design structure, a reasonable operating height, a small footprint, and a space and structure that is easy to clean.

2. The drive shaft and gear drive of the transmission system are driven by a servo motor or a frequency conversion motor, with low noise, easy maintenance, simple and environmentally friendly, and more accurate control.

3. The product chain and material chain have a large adjustment range. Within a certain range, direct adjustment can meet the production requirements.

4. The robot is used to grab the materials and pack them into boxes, so the work is accurate and stable.

5. The product conveying chain can be designed according to the actual material form and can be connected with a variety of feeding machines.

6. It can automatically place the cardboard and instructions.

7. Complete the upper and lower automatic sealing tape of the carton in a small space.

8. Synchronous conveying device can ensure the integrity of the cartons during the packaging process and ensure the appearance of the cartons.

9. The back end of the equipment can be connected with automatic baler, corner labeling machine and other equipment.

10. Control system:

◎The main electrical components adopt the French Schneider brand to ensure the high speed and stability of the control system;

◎Optimized arrangement and combination of various function buttons in the man-machine interface, which can more intuitively express various functions;

◎High-speed motion controller or programmable controller;

◎CANOPENG bus communication, strong anti-interference, fast transmission rate.

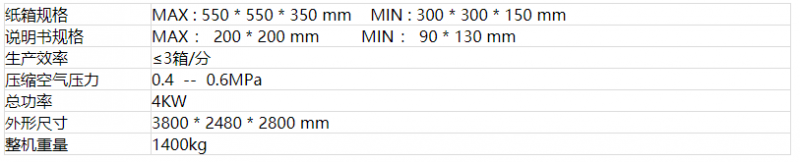

Technical Parameters

10 layers cell factory automation workstation

Ten layers cell factory automatic station is applicable to the automatic culture of ten layer cell factory, and can realize the whole process unmanned operation of automatic liquid filling, automatic liquid homogenization and automatic liquid discharge. The above process flow can act alone, with higher flexibility and richer adaptation to the scene.

2021-11-05Automated biopharmaceutical equipment

Automated biopharmaceutical equipment|CFAM cell factory automation equipment|

2021-07-03Cell mixer

The cell mixer can realize the weighing and stirring of the cells, so that the cells are fully uniform and high-precision weighing.

2021-07-03Aseptic filling equipment

This equipment is specially designed for filling bottles in an aseptic environment. Among them, automatic bottle unscramble, automatic bottle feeding, automatic filling, automatic capping and capping are high-tech filling equipment integrating machine and electricity. It has a high degree of automation and is applied to aseptic filling of bottles. This system is specially designed for customers. B

2021-07-03

Home

Home

phone

phone

note

note

contact

contact