The operator observes the culture in the multi-layer culture container, can observe the upper and lower surfaces at the same time, and the number of observation layers can reach 3 layers. Under software optimization, images can be simultaneously imaged in the display, which is convenient for operators to operate and observe. The visual system observation magnification can reach 100 times, and the morphological characteristics of the cells can be clearly observed.

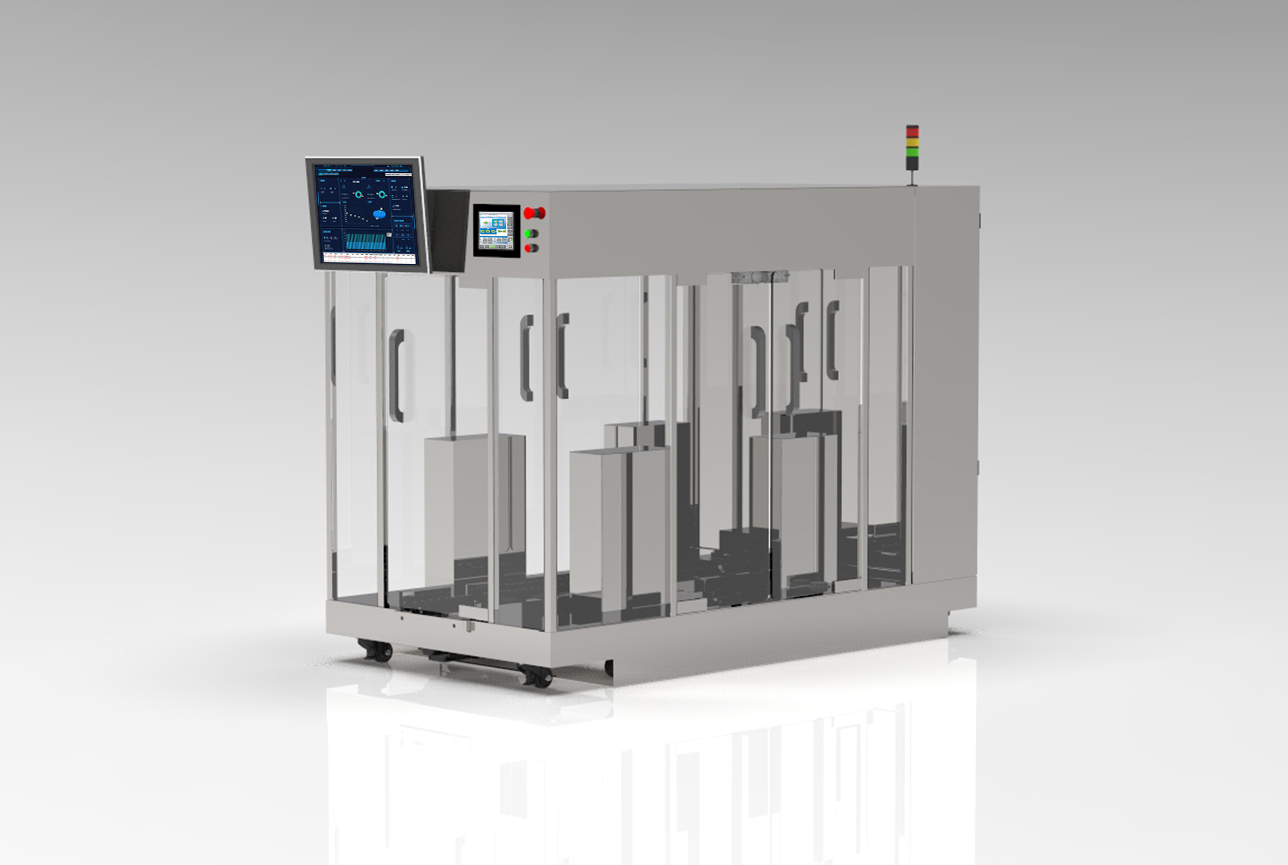

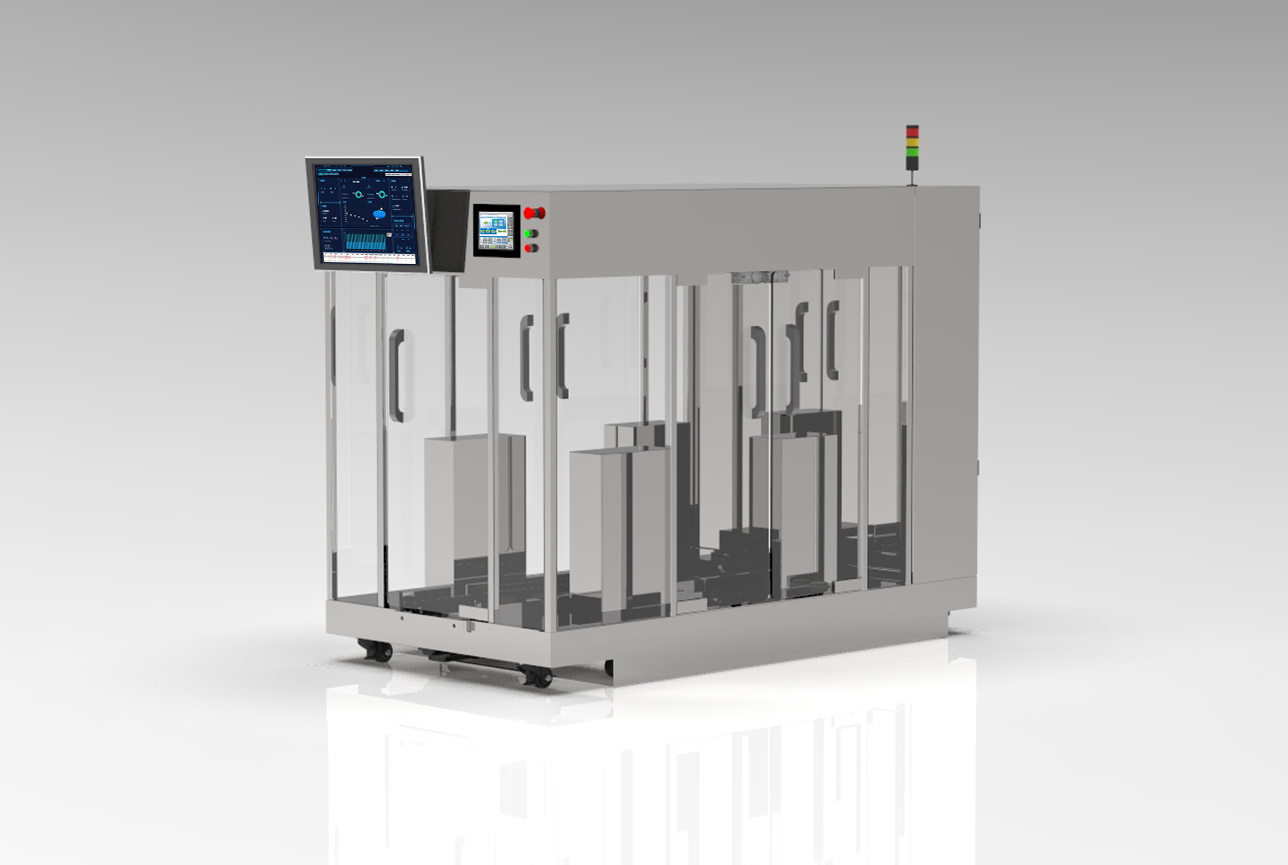

The device is mainly composed of four parts: main frame, lifting mechanism, upper and lower vision system and PLC software control. The main frame is mainly used to place the multi-layer culture container; the lifting mechanism is used to lift the multi-layer container to facilitate the observation of the bottom of the container; the upper and lower vision system is mainly used to observe the upper and lower surfaces of the multi-layer container to produce high-resolution image output To the display.

The operator pushes the multi-layer culture container that needs to be observed into the main frame of the observation device. The operator controls the lifting mechanism to rise on the touch screen, and the upper and lower vision system performs optical shooting to image the picture on the display. After the observation is over, the one-key vision camera resets and the lifting system resets.

Products are used in pharmaceutical, scientific research and other industries.

10 layers cell factory automation workstation

Ten layers cell factory automatic station is applicable to the automatic culture of ten layer cell factory, and can realize the whole process unmanned operation of automatic liquid filling, automatic liquid homogenization and automatic liquid discharge. The above process flow can act alone, with higher flexibility and richer adaptation to the scene.

2021-11-05Automated biopharmaceutical equipment

Automated biopharmaceutical equipment|CFAM cell factory automation equipment|

2021-07-03Cell mixer

The cell mixer can realize the weighing and stirring of the cells, so that the cells are fully uniform and high-precision weighing.

2021-07-03Aseptic filling equipment

This equipment is specially designed for filling bottles in an aseptic environment. Among them, automatic bottle unscramble, automatic bottle feeding, automatic filling, automatic capping and capping are high-tech filling equipment integrating machine and electricity. It has a high degree of automation and is applied to aseptic filling of bottles. This system is specially designed for customers. B

2021-07-03

Home

Home

phone

phone

note

note

contact

contact