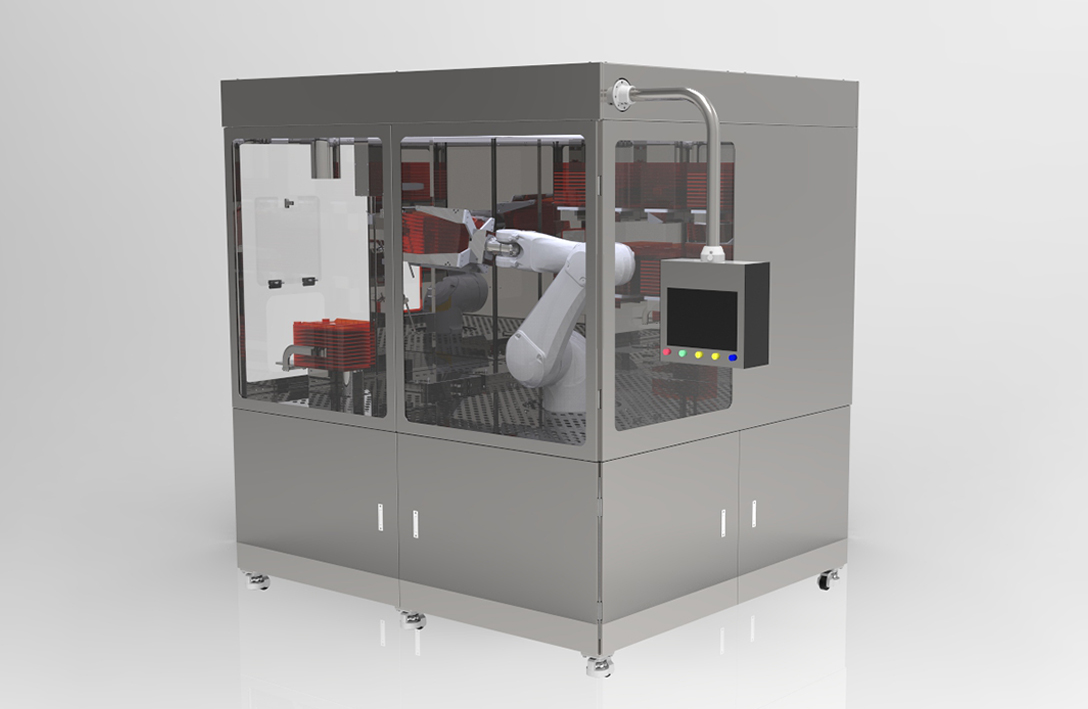

Pharmaceutical packaging workshop-palletizing robot

Release time:2021/7/3 15:32:45 Shenyang Great Elites Intelligent Equipment Co., Ltd.

Case Introduction

In a pharmaceutical packaging workshop of a pharmaceutical factory, after the front end is packed, the back end uses a robot to carry out the palletizing operation system.

Customer benefits

Save labor cost: After the robot is used for palletizing, it saves 2 manual operators for palletizing operations;

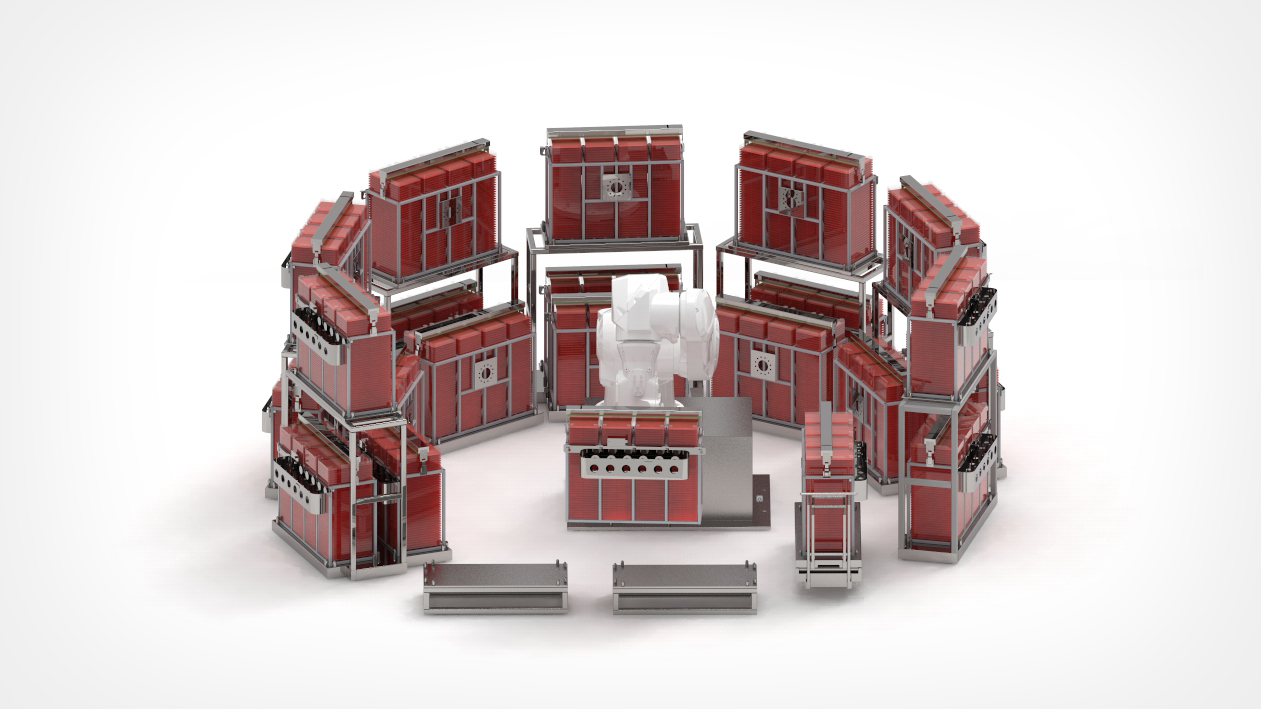

High flexibility: Due to the use of robots and bus control, rapid replacement of different varieties can be realized. At the same time, the layout can be flexibly adjusted according to the customer's site;

Small footprint: Robots are used for boxing and palletizing, so the total space occupied by boxing and palletizing is almost the same as that of individual palletizing;

Developed data interface: The system uses bus communication, so it can provide the upper computer with the operating data and control signals of the equipment, which is convenient for the subsequent docking of AGV and MES systems.

Home

Home

phone

phone

note

note

contact

contact