Vaccine production workshop-biopharmaceutical equipment-cell culture equipment

Release time:2021/7/3 15:27:53 Shenyang Great Elites Intelligent Equipment Co., Ltd.

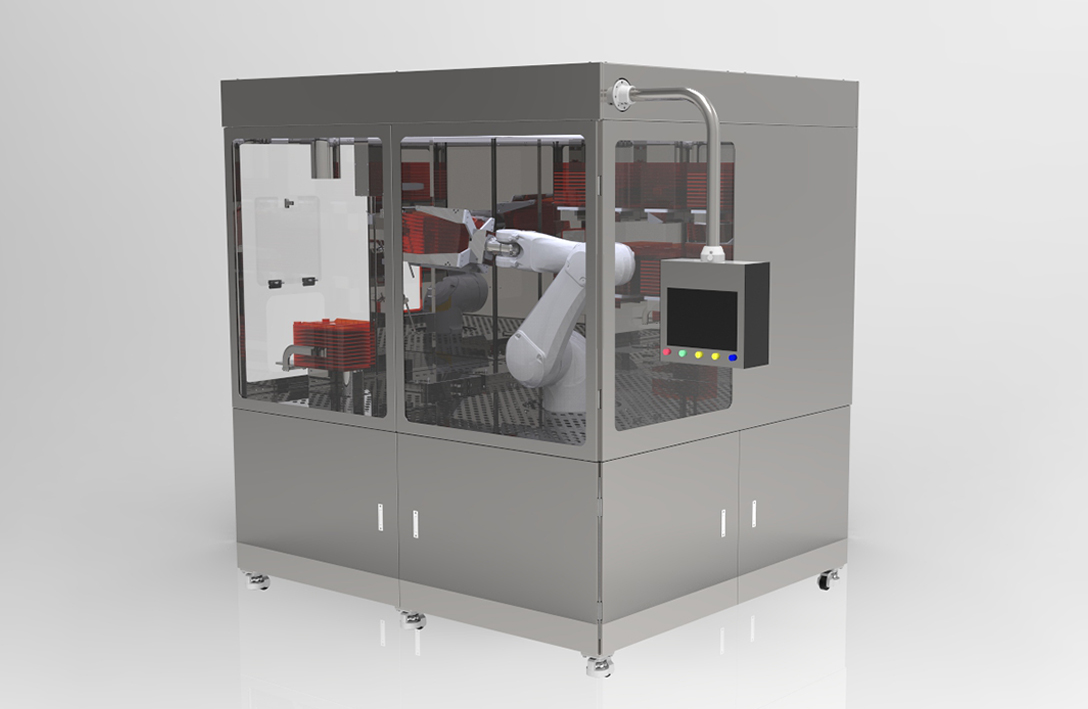

The CFAM series cell factory automation equipment of Shenyang Xinbang Intelligent Equipment Co., Ltd. is mainly used in biopharmaceuticals and cell doubling culture. Supporting hardware and software action programs can be customized according to customer process requirements, and automatic injection of vaccines and related cell culture processes can be realized , Draining, cell digestion and shaking, the liquid level automatically finds the equal function. It can support different types of cell factories such as 5-layer, 10-layer, and 40-layer. The equipment can meet the requirements of GMP A-level environment use and comply with GPM data management specifications.

▲Xinbang intelligent CFAM-40 cell factory automation equipment

Features

Meet GMP Class A cleanliness level, resistant to hydrogen peroxide (VHP) sterilization

The production process is efficient, safe and stable

Flexible and adjustable production process automation program

Reduce labor intensity of workers

Save labor and operating costs

Compatible with most cell factories

Customer case introduction

Customer Profile

Liaoning Chengda Biological Co., Ltd. was established in Shenyang in 2002 and has more than 1,000 employees. In terms of vaccine production technology, it has filled the domestic gap and reached the world's advanced level. Chengda Biosciences has successively developed more than ten kinds of vaccines such as human diploid rabies vaccine and Japanese encephalitis inactivated vaccine. Among them, human rabies vaccine has always maintained the first domestic market share and occupied an advantageous position in the international market. Product sales To more than 30 countries and regions.

▲Human rabies vaccine produced by Chengda Biological

Selection of equipment background

The Benxi branch of Chengda Biotechnology Co., Ltd. focuses on the innovation and replacement of traditional vaccines and the research and development of new products. In order to achieve the goal of producing 3-4 million injections per year, it is necessary to adopt highly automated production equipment. The production of vaccines using biotechnology is complicated and the equipment must meet the requirements With high stability and the highest cleanliness level, the new workshop of the hepatitis A vaccine and diploid rabies vaccine stock solution of the Benxi branch uses our company's CFAM-40 cell factory automation equipment to complete the task of processing the cell factory, creating this type of equipment in The first application in China's biotechnology vaccine production. The use of our company's CFAM-40 cell factory automation equipment brings higher production efficiency, shortens the time to market for products, and achieves the purpose of reducing costs and increasing efficiency and compliant production.

CFAM-40 cell factory automation equipment solution

The Xinbang intelligent technology team provided Chengda Biologics with a customized overall solution for vaccine cell culture. The service provides the pre-embedded plan from the plant construction stage, the equipment electrical circuit layout plan, the optimized use of the space layout plan, communication with the plant construction party, the planning of the room door position plan, the equipment transportation and entering the workshop plan, the debugging of the equipment and the auxiliary improvement process The process, etc., to the final completion of GMP certification. Xinbang Intelligent's strong technical research and development team and good after-sales service escort the production process of customers.

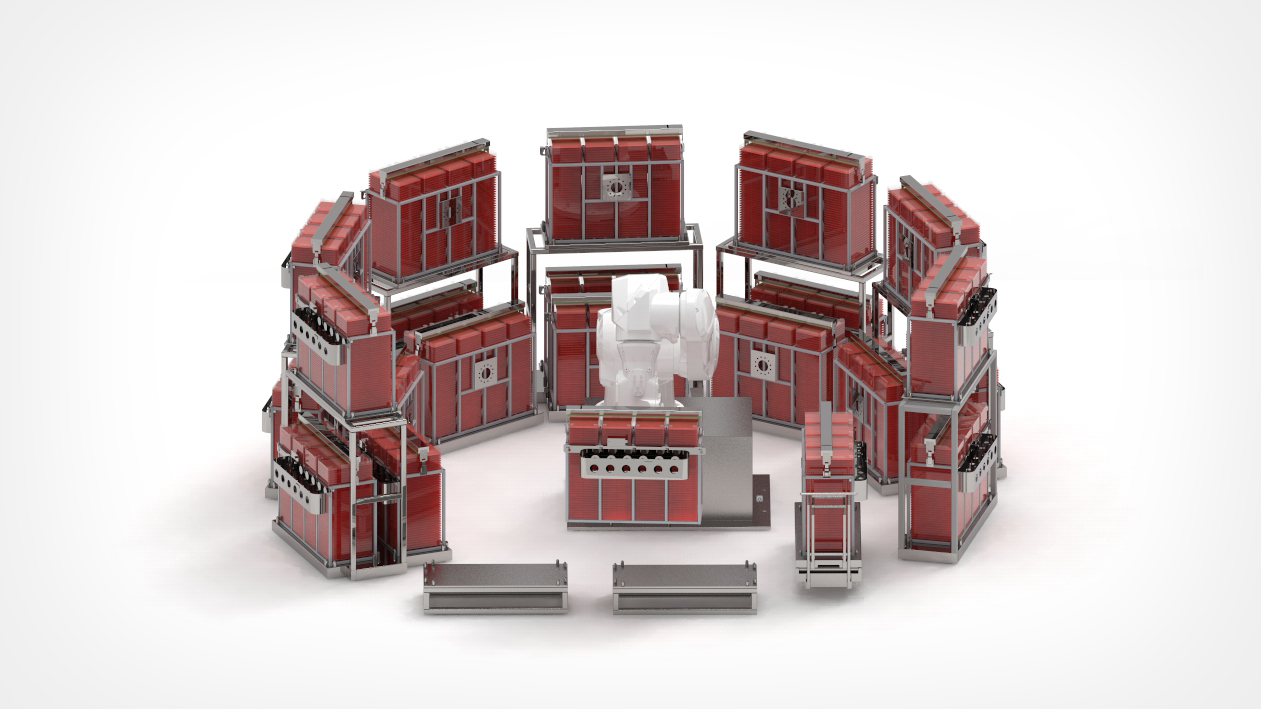

Cell culture stage: The stainless steel frame of the CFAM-40 cell factory automation equipment is equipped with 40-layer cell factories, and each layer of the cell factory is equipped with culture medium, and adherent cells are inoculated in the culture medium. In the process of cell growth, as nutrients are consumed, the culture medium in the petri dish needs to be replaced, and then virus-infected cells and virus culture medium are added, and finally the virus of this highly effective vaccine is harvested.

▲Xinbang Intelligent 40-layer Cell Factory Framework

Equipment operation stage: CFAM-40 cell factory automation equipment uses Stäubli TX200 aseptic robot to operate the cell factory. For the cell factory frame pushed to the positioning point, after the vision system is positioned, the robot first places the arm in front of the frame, connects it with the frame through a clamp, and then grabs the cell factory and places it at the predetermined position for cell growth. The robot will regularly shake and flip during the different stages of cell culture to distribute the liquid evenly. After the process flow is completed, the cell factory frame is placed in a predetermined position. The entire cell culture process lasts for more than 10 days, and any cell factory can be observed and operated during the culture process. In the cell phase, the robot distributes the culture medium and cells evenly in the petri dish by oscillating motion; in the liquid exchange phase, the cell fluid is poured out with the help of the robot; in the virus harvest phase, the robot collects viruses and cells in each layer ; At the stage of collecting the empty cell factory, the robot grabs the empty cell factory frame and places it on the transfer vehicle, and the whole process ends.

▲ CFAM-40 cell factory automation equipment in Chengda's biological vaccine cell culture workshop

Equipment operation: The operator can perform the process operation of the vaccine cell culture stage on the equipment in the workshop through the touch screen.

▲Separation of Chengda's biological vaccine training workshop and operation workshop

Benefits to customers after device application

Customer's evaluation and cooperation with Xinbang Intelligence

Chengda Biotech is very satisfied with our CFAM-40 cell factory automation equipment solutions, technical services and after-sales training.

Home

Home

phone

phone

note

note

contact

contact