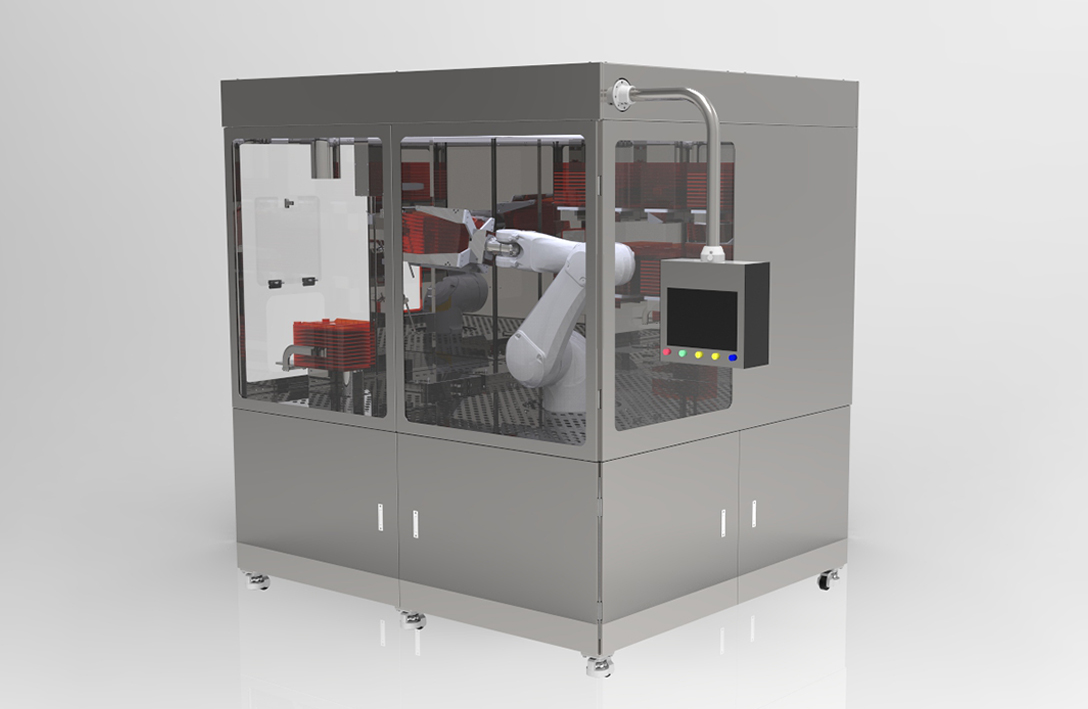

Insulin production workshop-destacking robot

Release time:2021/7/3 15:27:04 Shenyang Great Elites Intelligent Equipment Co., Ltd.

Case Introduction

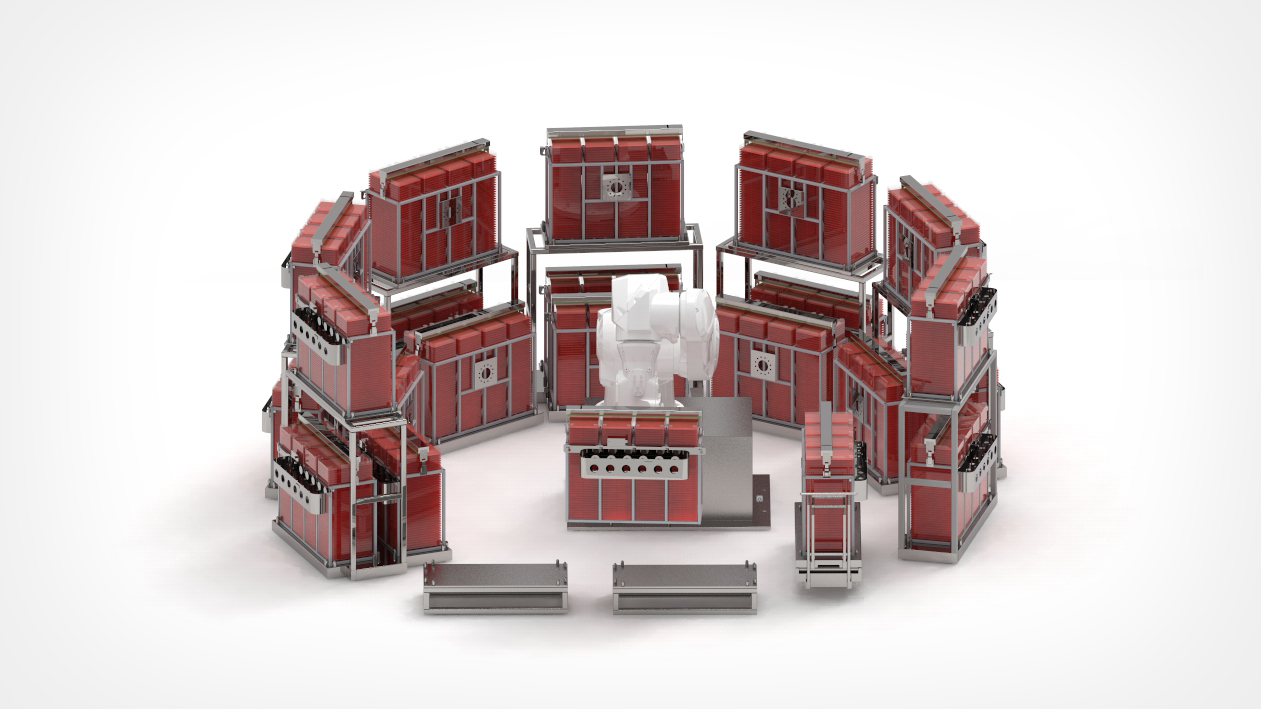

In the insulin production workshop of a pharmaceutical factory, a destacking robot is used to automatically unpack the urea. The robot grabs the urea bag from the surface urea stack, and cuts the urea packaging bag at the broken bag. The urea falls into the hopper and the waste bag Sent to the waste bag conveyor belt.

After visual inspection and taking pictures and positioning, the robot grabs the upper urea bag and places it at the unpacking place to unpack. The blade cuts the flour packaging bag and the flour falls into the lower funnel; the waste bag is placed on the waste bag conveyor belt.

Customer benefits

1. Automation equipment and robots have replaced a lot of labor (the original 15 workers were needed for each line, but now it has been reduced to 3), and the cost can be recovered in two years;

2. The addition of automation equipment and robots ensures the stability of production;

3. Improve production efficiency and production quality;

4. The working environment has been greatly improved, the cooperation confidence of partners has been enhanced, and the company's image has been improved.

Home

Home

phone

phone

note

note

contact

contact