The biopharmaceutical industry is valued, and pharmaceutical-related equipment will welcome new comp

Release time:2021/7/5 9:48:28 Shenyang Great Elites Intelligent Equipment Co., Ltd.

According to the industry, innovation and development deserve the attention of the pharmaceutical equipment industry, and related biomedical equipment will become more abundant. Many pharmaceutical equipment companies are constantly expanding their product lines and further broadening their equipment product series to seize favorable opportunities. For example, in order to cater to the general trend of biopharmaceutical development, some companies have further broadened their product series, launched targeted biopharmaceutical equipment, and formed orders. "In the future, these biopharmaceutical equipment will become a new profit growth point."

So, in the field of biopharmaceuticals, what are the current common biopharmaceutical equipment? This article mainly introduces double-layer glass reactor, biological process bag tester, stirred reactor, and sterilization equipment.

Double-layer glass reactor

The working principle of the double-layer glass reactor is to inject constant-temperature hot melt media or cooling media through the interlayer of the double-layer reactor, and operate constant-temperature heating or cooling of the materials in the reactor, and can provide stirring. The material runs and reacts in the reaction kettle, and can control the evaporation and reflux of the reaction solution. After the reaction is completed, the material can be discharged from the discharge port at the bottom of the kettle, and the operation is convenient. It is an ideal equipment for modern chemical sample, medium sample experiment, biopharmaceutical and new material synthesis.

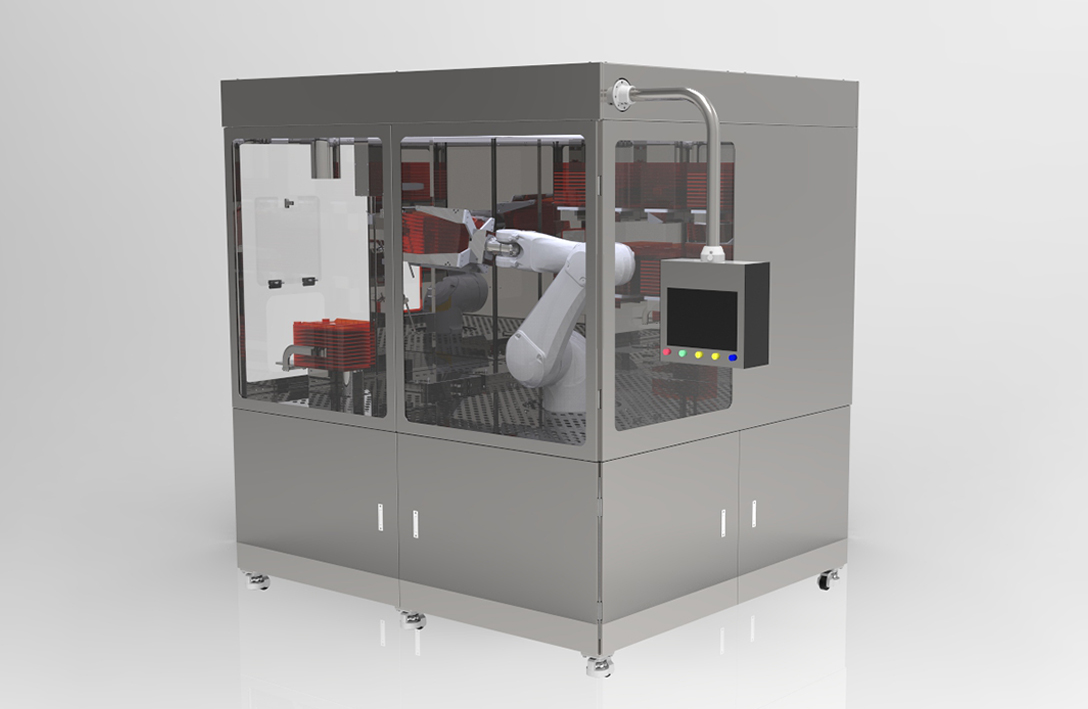

Bioprocess bag tester

The bioprocess bag tester is a device specially designed by biopharmaceutical equipment companies, which can be used for integrity testing of disposable bioprocess bags in bioreactors.

In order to reduce the loss during operation, pharmaceutical companies need to use the bioprocess bag tester to improve the production efficiency of biopharmaceutical companies.

It is reported that the bioprocess bag tester uses a technology to test the bioprocess bag at the point of use in a non-destructive manner. The rapid test method has been verified in many ways, fully automatic operation, and its principle is pressure attenuation. . In terms of avoiding the risks caused by manual operation, the bioprocess bag tester will be an effective choice for enterprises.

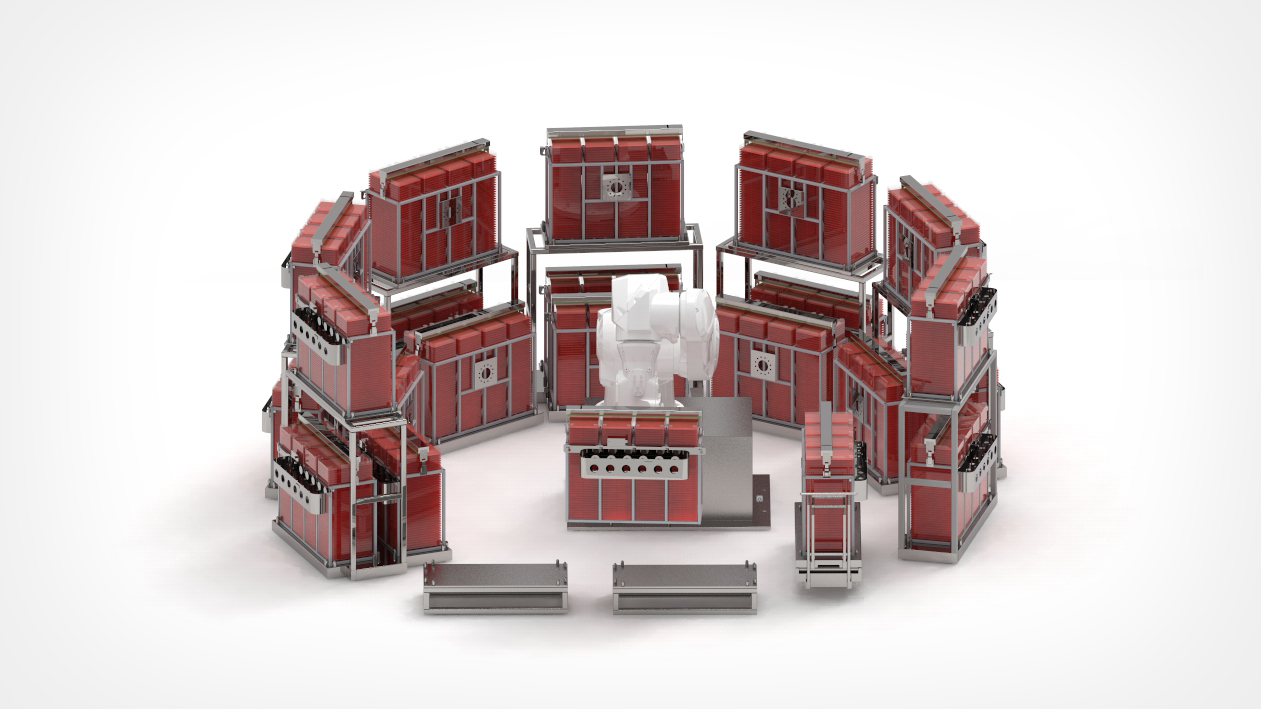

Stirred reactor

Under aseptic production conditions, magnetic stirring is an ideal cell culture technique, and magnetic stirrers are different from sliding-sealed stirrers. The stirring blade of the magnetic stirrer can be isolated from the non-sterile environment by carefully designed peripheral equipment, and the magnetic coupling drive device is very tightly sealed; the magnetic coupling cannot enter and exit the isolation device, so the pollution risk is close to zero.

Sterilization equipment

In the biopharmaceutical field, sterilization process and sterilization equipment are crucial parts. The production of sterile drugs must meet the quality requirements and prevent the contamination of various microorganisms and particles. Therefore, the choice of high-quality sterilization methods and equipment is conducive to ensuring the quality of the product.

In the field of sterilization, domestic sterilization equipment has been continuously developed in recent years and has made great progress. It can basically meet the needs of the low-end market. However, compared with the 60~90% penetration rate of developed countries such as Japan, South Korea, Europe and the United States, the domestic In the market, the penetration rate of disinfection and sterilization equipment is as low as about 5%, so the current market situation is still not optimistic.

At present, some domestic sterilization equipment companies are keeping up with the international pace, regularly doing cGMP project design, certification, consulting, consulting and training, etc., and domestic manufacturing, module manufacturing and stainless steel product processing for European and American pharmaceutical equipment to further meet the needs of domestic production. demand.

Home

Home

phone

phone

note

note

contact

contact