Robot control system classification and basic functions

Release time:2021/7/5 9:44:12 Shenyang Great Elites Intelligent Equipment Co., Ltd.

The internal sensor signal of the robot is used to reflect the actual motion state of the robot arm joints, and the external sensor signal of the robot is used to detect changes in the working environment.

Robot control system classification (according to control method)

1. Centralized Control System (Centralized Control System)

A computer is used to realize all control functions. The structure is simple and the cost is low, but the real-time performance is poor and it is difficult to expand. This structure is often used in early robots.

Its advantages are: low hardware cost, easy to collect and analyze information, easy to achieve optimal control of the system, better integrity and coordination, and more convenient for PC-based system hardware expansion.

The disadvantages are: the system control lacks flexibility, and the control danger is easy to concentrate. Once a failure occurs, its impact is wide and the consequences are serious; due to the high real-time requirements of industrial robots, when the system performs a large number of data calculations, it will reduce the real-time performance of the system. The responsiveness to multitasking will also conflict with the real-time nature of the system; in addition, the complex connection of the system will reduce the reliability of the system.

2. Master-slave control system

The master and slave two-level processors are used to realize all the control functions of the system. The main CPU realizes management, coordinate transformation, trajectory generation and system self-diagnosis, etc.; the slave CPU realizes the motion control of all joints. The master-slave control system has good real-time performance and is suitable for high-precision and high-speed control, but its system scalability is poor and maintenance is difficult.

According to the nature and method of the system, the system control is divided into several modules. Each module has different control tasks and control strategies. Each mode can be a master-slave relationship or an equal relationship. This method has good real-time performance, is easy to realize high-speed, high-precision control, is easy to expand, and can realize intelligent control. It is a popular method at present.

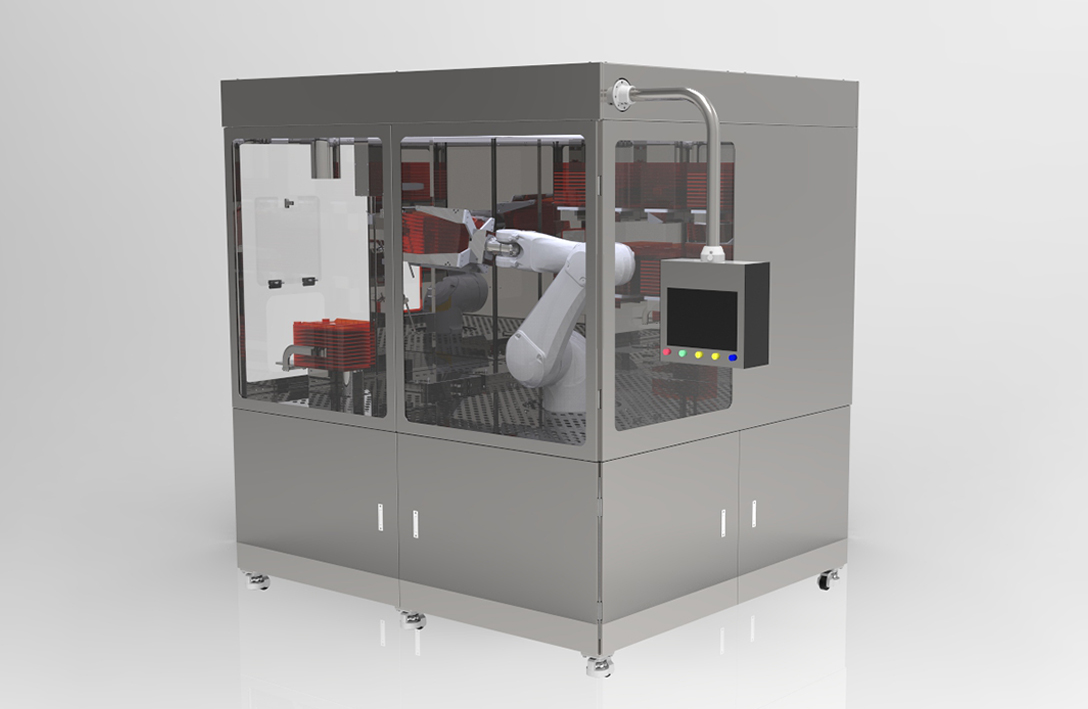

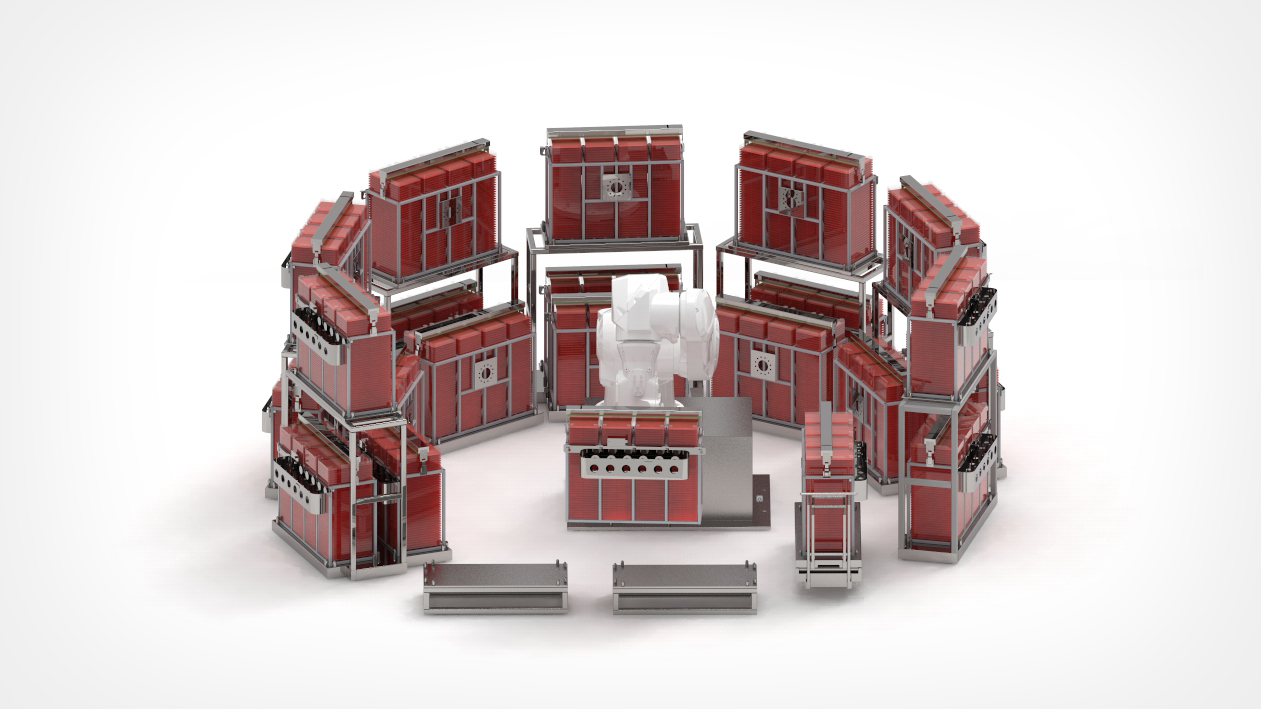

Shenyang Robot System

Basic functions of robot control system

1. Control the movement position of the end effector of the robotic arm (that is, control the point and movement path passed by the end effector).

2. Control the movement posture of the mechanical arm (that is, control the relative position of two adjacent movable members).

3. Control the movement speed (that is, control the law of the end effector's movement position with time).

4. Control the movement acceleration (that is, control the speed change of the end effector during the movement).

5. Control the output torque of each power joint in the mechanical arm (that is, control the force applied to the operating object).

6. With easy-to-operate human-computer interaction function, the robot completes the specified tasks through memory and reproduction.

7. Enable the robot to detect and feel the external environment. Industrial robots are equipped with vision, force, and tactile sensors to measure, identify, and judge changes in operating conditions.

Home

Home

phone

phone

note

note

contact

contact