Modern robot intelligent palletizing system

Release time:2021/7/3 17:36:07 Shenyang Great Elites Intelligent Equipment Co., Ltd.

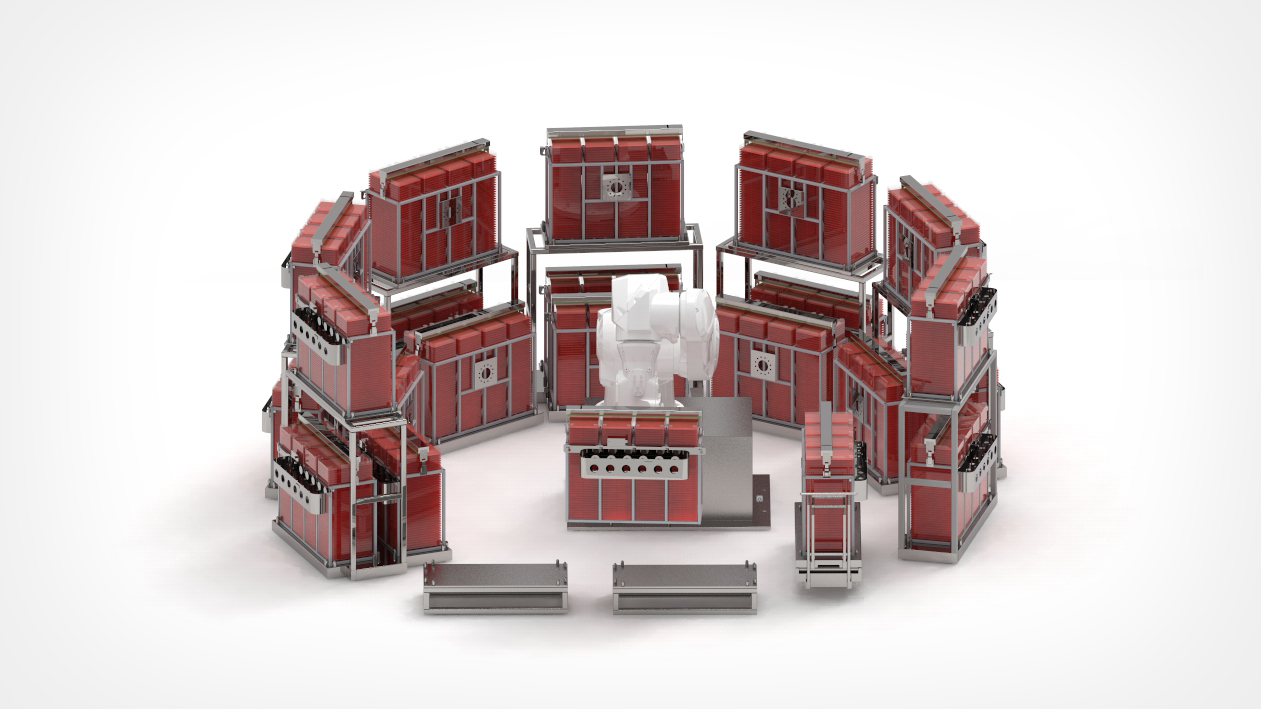

The palletizing robots we used in the past usually only palletized products of the same type and size. The intelligent palletizing & depalletizing system of modern robots has raised the difficulty to a level. By matching with 3D vision equipment, it can complete the automated palletizing and depalletizing operations of boxes or other items of different sizes and shapes. Realizable scenarios More abundant.

01.3D Vision

First of all, through the loading 3D vision equipment, check and confirm the best position for destacking to achieve the most effective loading.

02. Special fixture

The system uses special fixtures for palletizing and depalletizing, which can not only pick up boxes or packages, but also compressed packaging products.

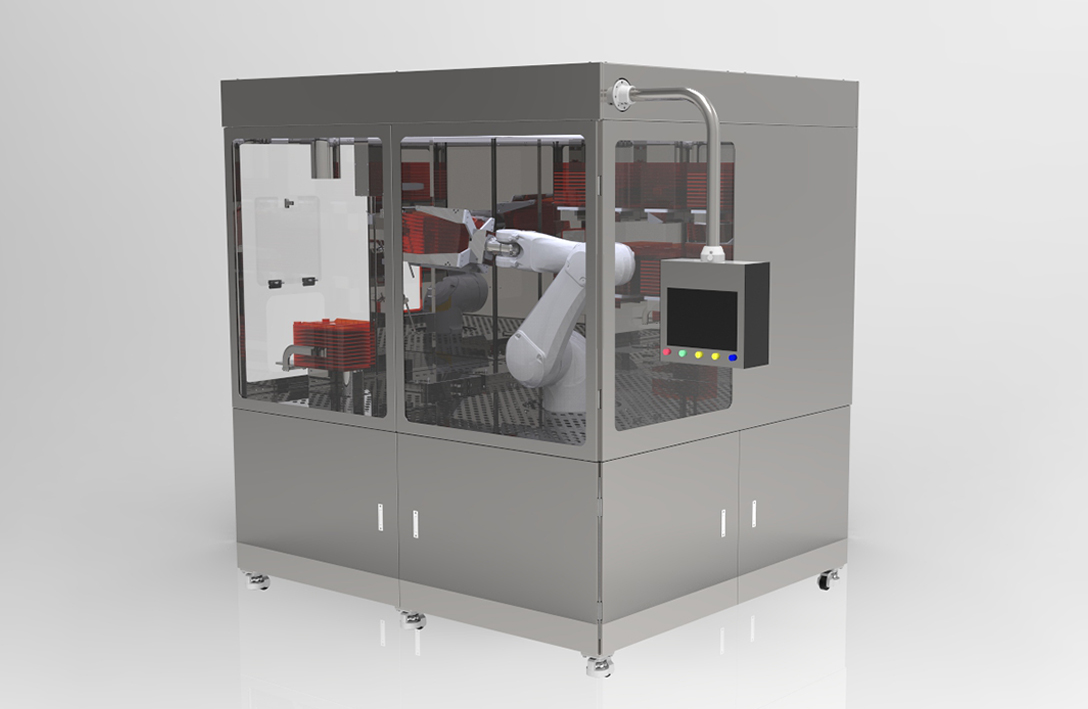

Palletizing system

03. Smart Palletizing & Depalletizing

Next, use 3D vision to identify various types of transportation boxes, and then use a robot (YS140) to automatically pick up the boxes and arrange them on the pallet.

The modern YS140 robot used in this system is an industrial robot with a load of 140kg, with a working range of 2339mm and an accuracy of ±0.15mm. In addition to palletizing, it can also be used for spot welding, handling, gluing and other application scenarios.

For food, beverage and other product lines, as well as e-commerce and other industries, its logistics center needs to handle a large number of packages of different products every day. The intelligent palletizing & depalletizing system of modern robots can perfectly adapt to these processing scenarios, and respond and provide timely The most optimized solution.

Combined with the HRMS modern robot management system, it can realize real-time monitoring of the robot's running status, and carry out fault warning, and predict the robot's maintenance information in advance according to the algorithm. At the same time, it can be easily interconnected with the enterprise's ERP, MES and other systems to facilitate the collection and management of data.

The use of intelligent palletizing system can achieve more intelligent operation management, which can greatly reduce labor and labor intensity, realize 7 X 24 hours all-weather operation, improve the production efficiency of the enterprise, improve the management level and automation level of the enterprise, and help the enterprise Obtain more competitive advantages in the industry 4.0 era.

Home

Home

phone

phone

note

note

contact

contact