Who will lead the development of continuous biological manufacturing?

Release time:2021/7/3 17:35:06 Shenyang Great Elites Intelligent Equipment Co., Ltd.

When a disruptive technology emerges, the first mover is usually not a larger, established company. Some large companies in the field of biotechnology are now willing to invest in continuous biomanufacturing because they hope to incorporate the technology directly from the development stage of new products.

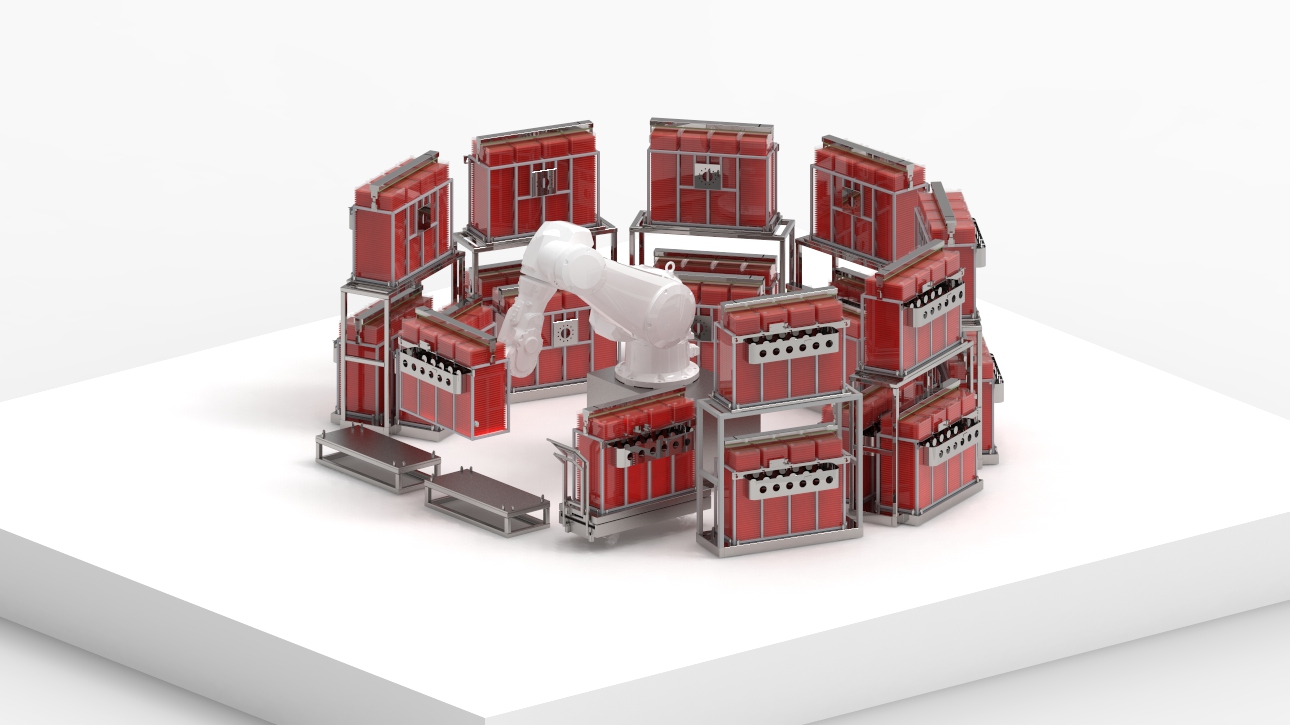

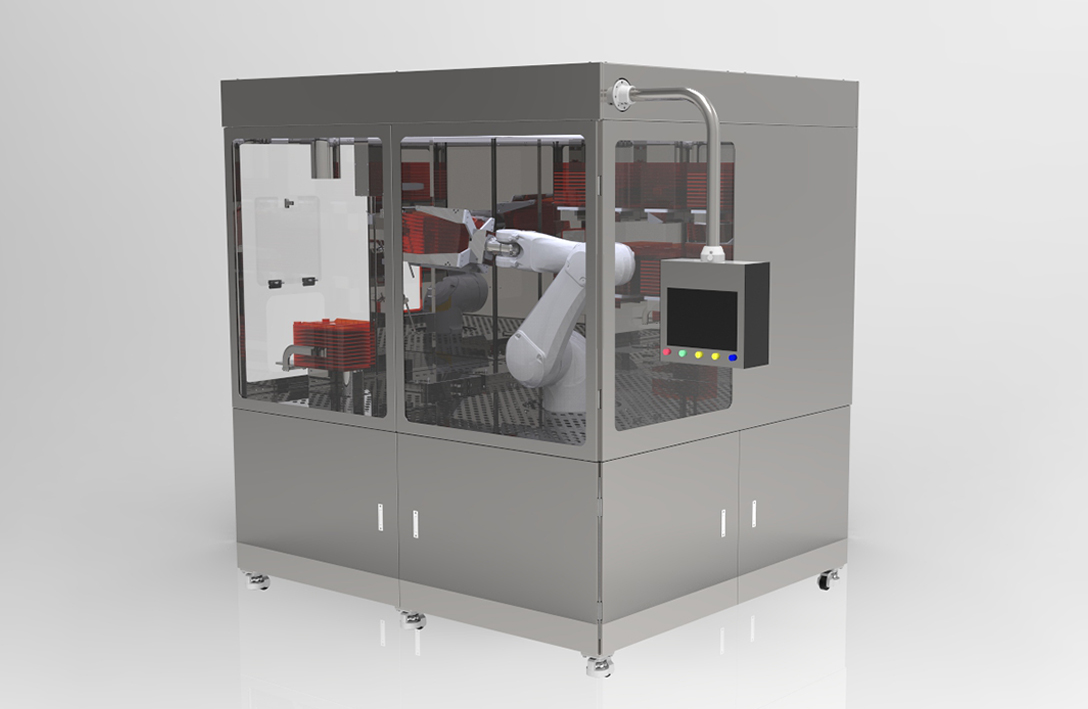

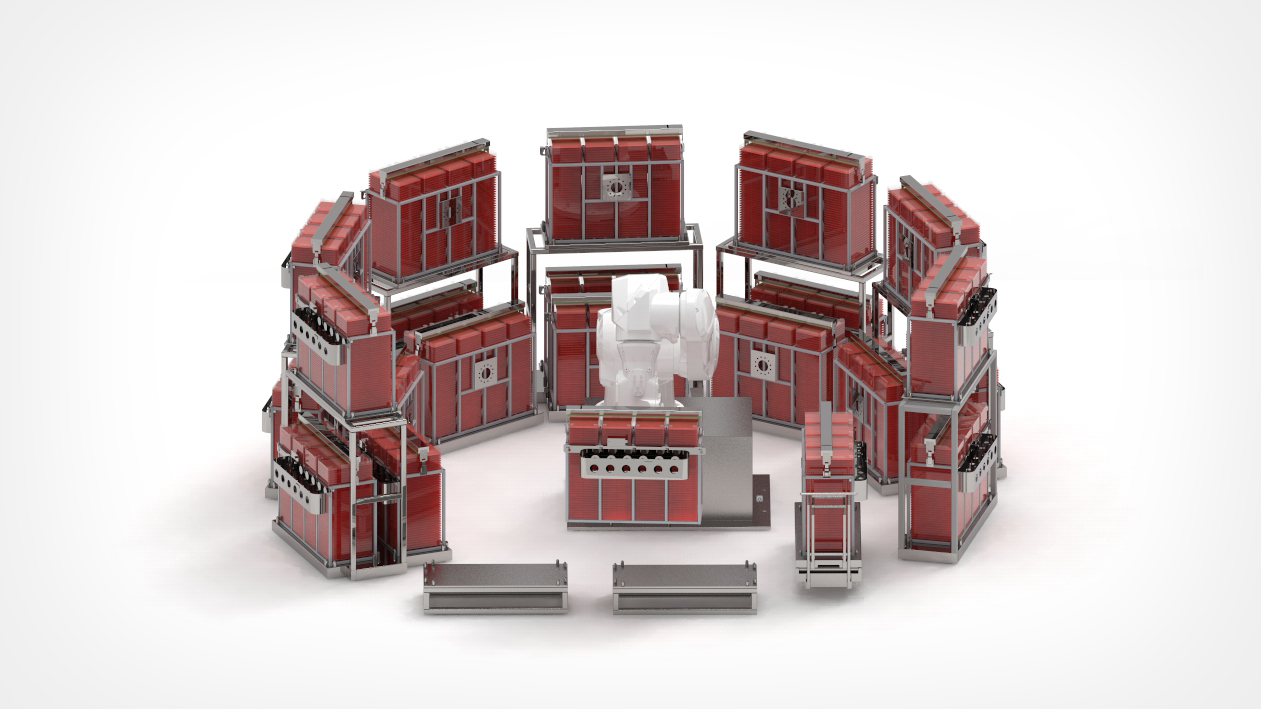

Production equipment suppliers are also participating in this competition. If their equipment can enter the market first, the return on investment will be faster. They not only actively seek to establish strong partnerships with large biotechnology companies, but also maintain close contact with regulatory agencies, hoping to allow regulatory agencies to participate as soon as possible to lead the industry's development trend. In addition, the active participation of large companies that are both equipment suppliers and API suppliers can more fully justify the rationality of continuous bio-manufacturing investment. Because they not only want to increase their productivity, but also want to commercialize the newly developed platform.

Our global project prospects show that many companies already have the technology and potential suitable for the development of continuous biological manufacturing. In the next step, the industrialization of continuous biological manufacturing will depend on the growth of relevant cases, reliable economic data and actual product quality.

Home

Home

phone

phone

note

note

contact

contact