Talking about the application of machine vision in the field of biopharmaceuticals

Release time:2021/7/3 17:34:10 Shenyang Great Elites Intelligent Equipment Co., Ltd.

1. Machine vision detection of lack of medicine or lack of bottles

Due to the strict regulations of the pharmaceutical industry, the quality of pharmaceutical packaging is becoming more and more demanding. When the drug pellets are packed into the blister, the manufacturer must ensure that all the drug pellets in the blister are intact; or, when the drug leaves the factory At the time, ordinary bottled medicines are all geometric bottled medicines packed in a larger package, and the manufacturer must ensure that there is no shortage of medicine bottles in each package to avoid the impact on the reputation of the drug manufacturer.

Solution: Using machine vision skills, you can quickly and accurately detect whether the object is intact. By setting the image sensor, you can obtain the image information of the packaged object, and use the preset area parameter to analyze each medicine pellet or bottle. Perform inspection and comparison. In this way, broken medicine pellets or packages with missing bottles will be detected and passed normally.

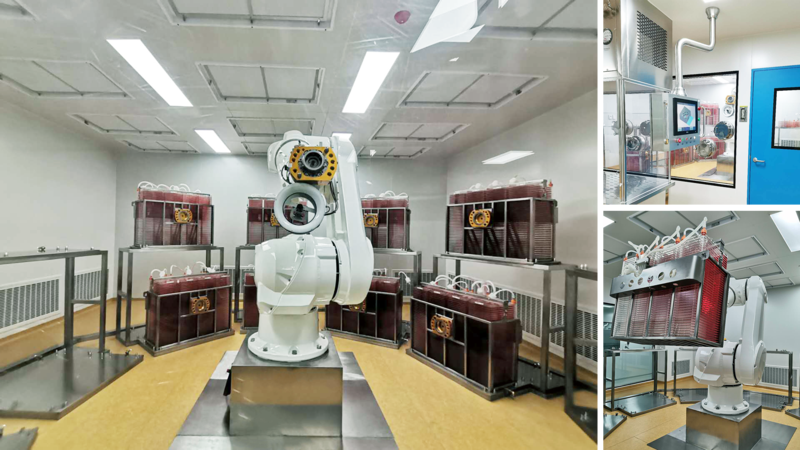

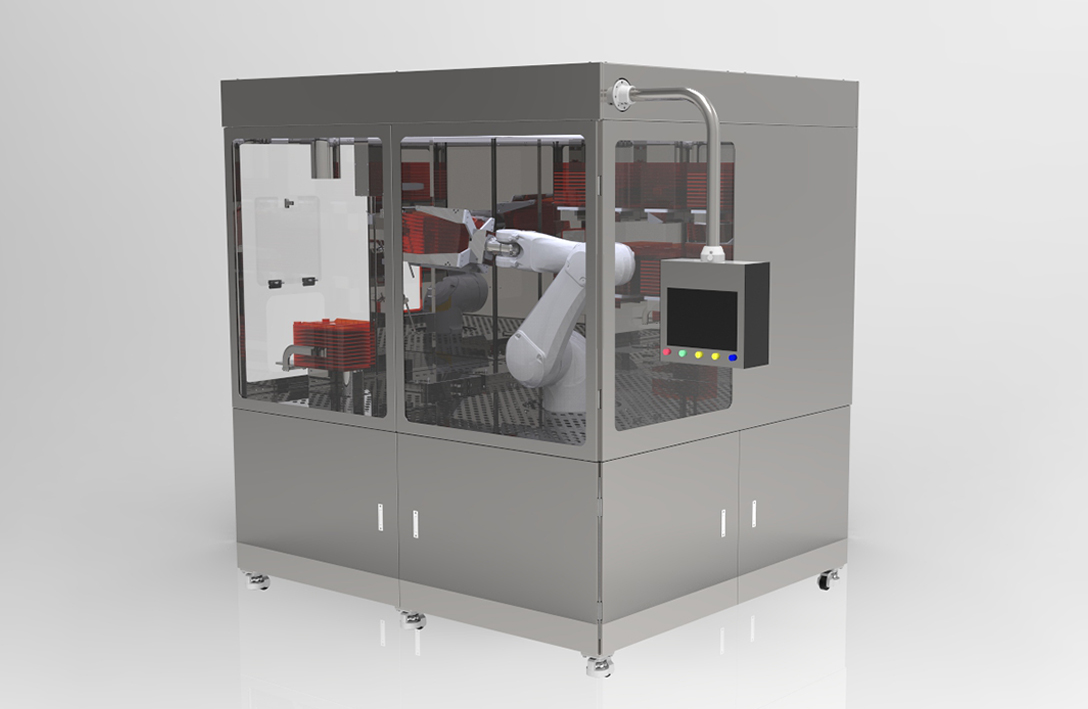

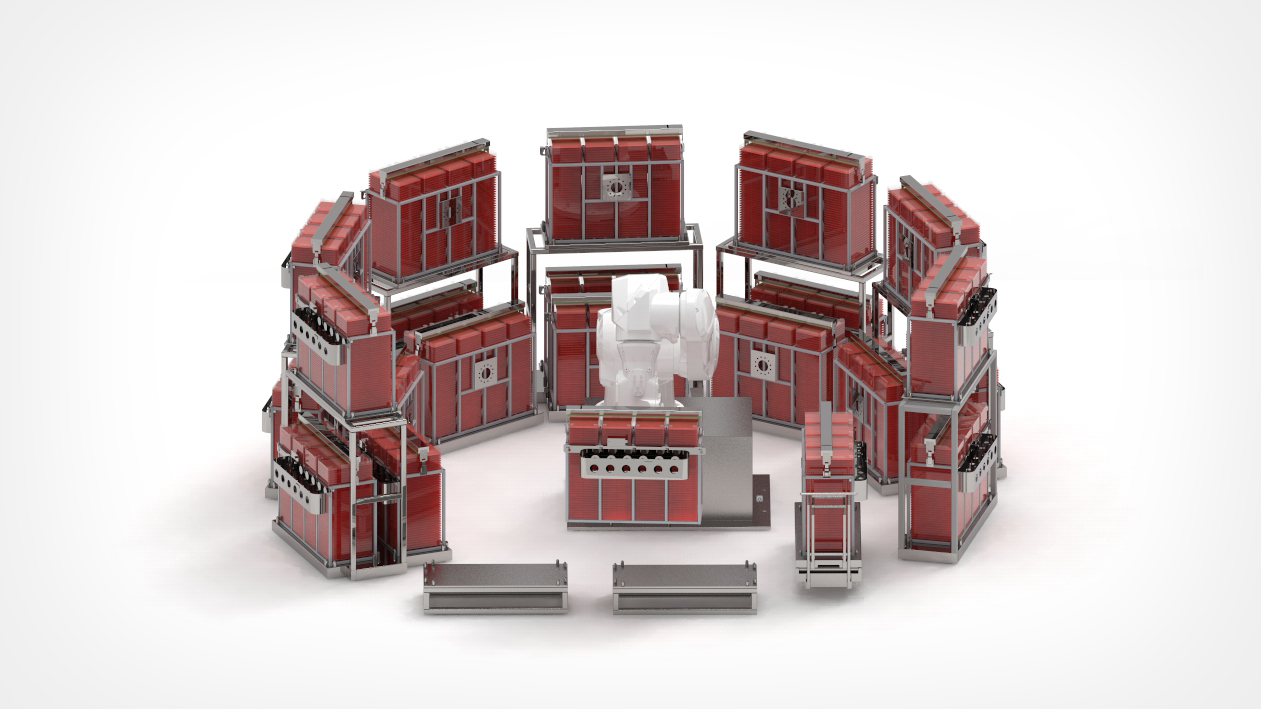

Biopharmaceutical equipment

2. Machine vision bottle mouth damage detection

After the liquid medicine bottle is canned, it is necessary to check whether the mouth of the bottle is damaged, which is related to whether the liquid medicine will be mixed with glass fragments.

Solution: After installing the image sensor in the liquid medicine canning process, check whether the bottle mouth is damaged or not through the graphic matching object. Before detection, the image sensor records the usual bottle mouth characteristics. When the canned medicine bottle passes in front of the sensor lens, the sensor captures the current bottle mouth characteristics and compares it with the original bottle mouth characteristics it imaged to see if If they are different, the sensor will emit a light signal to reject the bottle by the rejection mechanism. The user can set the similarity degree according to the characteristics of the bottle mouth through the vision software. It is assumed to be set to 90%, that is, when the characteristic similarity of the detected bottle mouth and the sensor image is 90% or more, the sensor It was determined that the mouth of this bottle was intact. After this test, all medicine bottles with broken mouths can be eliminated.

Home

Home

phone

phone

note

note

contact

contact